Breaking into the Closed Circle: Domestic High-Tech Manufacturing Needs Access To Markets

The article by Shyam Ponappa (originally published in the Business Standard on July 31, 2013) was cross-posted in Organizing India Blogspot on August 1, 2013.

There are compelling reasons for supporting domestic manufacturing capacity in India, and high-tech products deserve high priority. Examining the elements of the proposition for developing our high-tech manufacturing and the state of its capacity may help clarify where and how policies should be heading. If domestic electronics production does not increase significantly, India's electronics requirements will be choked by high imports in excess of even oil imports.

The Bogey of Protectionism

The aim of the PMA policy is to give technically qualified domestic manufacturers access to otherwise closed domestic markets. It only provides an opening, and does not provide any protection or price preference. The notification states explicitly that technically qualified domestic manufacturers are eligible only if they match the lowest bid; if there are no qualified local manufacturers, or if qualified vendors don't match the lowest bid, entire orders may be awarded to the lowest-priced vendor/s (from abroad). Perhaps there is some confusion arising from the nomenclature, as "PMA" usually refers to international vendor access to domestic markets. The notion that the PMA is protectionist and shields domestic suppliers from competition is incorrect.

Deferring PMA to Assess Domestic Capabilities

The government's deferral of the PMA pending assessment of domestic manufacturing capabilities appears unreasonable, as there are already qualified manufacturers in India, several of them transnationals, producing high-tech products for global markets. The top 10 global fabless design companies and the top 25 semiconductor companies operate in India. In 2010, revenues were estimated at $7.5 billion, and in 2012, over $10 billion. India is reportedly among the top countries for fabless design skills, and has the critical ingredients for the growth of fabless companies as start-ups slow in the West: design service companies, design engineering expertise and innovation, returning entrepreneurs, and educational facilities. What they need for scale is local market access, equity funding, good logistics, and effective infrastructure. These are the areas where the government can facilitate matters. Deferring access to local companies at a time of rapid growth in networks will entrench foreign products, providing them with an undue advantage against local producers. Instead, we should be capitalising on our domestic strengths.

Closed Circle of Buyers & Sellers

In high-technology procurement, large international vendors, of whom there are relatively few, form long-term relationships with the relatively few large buyers in oligopolistic markets in telecommunications or electricity. This holds whether the buyers are government entities, state-owned enterprises, or private sector companies. Often, the international vendors have strong home government support. This is why domestic manufacturers need mandatory access to break into a closed circle. There is no ambiguity in this, nor is it protectionist, and there are no price preferences - in contrast to the 15 per cent allowed by the World Bank, or 10 per cent for minority-owned businesses in the United States.

Markets & Demand

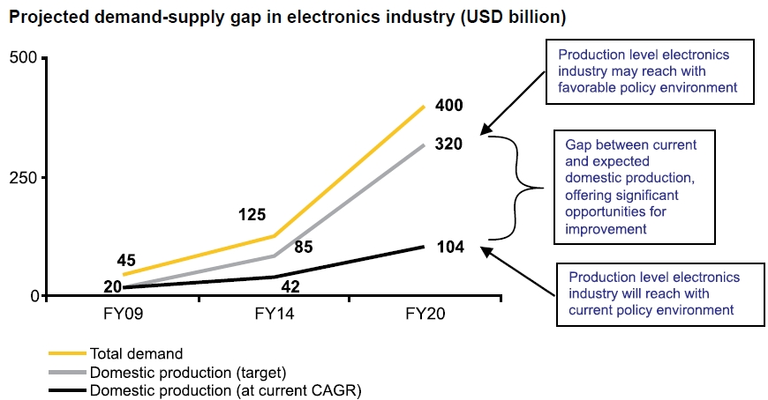

Of the many reasons for developing electronics manufacturing capabilities in India, a compelling one is our level of demand for electronics. A task force comprising government and industry participants estimated in 2009 that demand in 2009-10 was around $45 billion, going up to $70 billion in 2012, and projected at $400 billion by 2020 (see chart), with government's share being 40 per cent.

|

|---|

| Source: http://deity.gov.in/hindi/sites/upload_files/dithindi/files/Task_Force_Report-new_21211.pdf |

Domestic production was at $20 billion in the financial year 2009 while imports were $25 billion, projected to rise to over $300 billion by 2020 if domestic production maintained its trend to reach $104 billion. However, with appropriate policies including the PMA for local manufacturers, in the best case, domestic electronics manufacturing was estimated to increase to over $300 billion. If this could be achieved, India's electronics imports would amount to about $100 billion. Without it, imports of $300 billion may be needed, exceeding even estimated oil imports.

Security Screening/Auditing of Imports

High-security applications in the US, Japan, Israel and China are procured from trusted domestic manufacturers. The US Congress monitors high-tech imports for strategic reasons. The UK is conducting an investigation into whether its broadband networks have been compromised by foreign suppliers, although malware is very difficult to detect, and can be downloaded after security audits. High-tech supplies need to be from trusted sources.

Domestic Producers vs Other Lobbies

In effect, it would seem that the operators and foreign vendors have railroaded the government into perpetuating the status quo of foreign-dominated electronics suppliers in India. Facilitating access to local markets for domestic manufacturers is the kind of support that many governments provide. Take the case of the "Buy American" provisions of the American Recovery and Reinvestment Act of 2009. Recovery Act funds used for the construction, alteration, maintenance or repair of public buildings and public works must procure all iron, steel and manufactured goods produced only in the US, with a price preference of 25 per cent. The exceptions are non-availability, prices of over 25 per cent, or where applying the provisions is against the public interest. The objectives were to save and create jobs, to give relief to those affected by the recession, and to invest in infrastructure, education, health and renewable energy. The estimated cost is $831 billion between 2009 and 2019.

Remedial Action

What's needed is for the government to take unequivocal action without delay on enabling policies for domestic high-tech producers. The sooner this is done, and the more sustained support that is provided, the better. Too many confused signals are being sent out on investments.